Aspen Basic Engineering

|

|---|

| Enables concurrent basic engineering, produces basic engineering deliverables, and

supports lifecycle process engineering. Aspen Basic Engineering is a scalable, global process engineering platform, tying together all elements

of front-end design.With a focus on the basic engineering function, Aspen Basic Engineering provides

tight integration with the latest releases of all major process simulation, cost estimation, and equipment

design programs—whether they’re commercially available or developed in-house.

(一)、The Challenge: DoMore with Fewer Engineers With capital project investments in an upward cycle across the process power, generation and mining industries, design work on

these projects faces a global shortage of experienced engineers.More specifically, Aspen Basic Engineering addresses these key

business issues in the process engineering function:

(二)、The Solution: Integrated Process

Engineering for Fast, Accurate,

Consistent Results

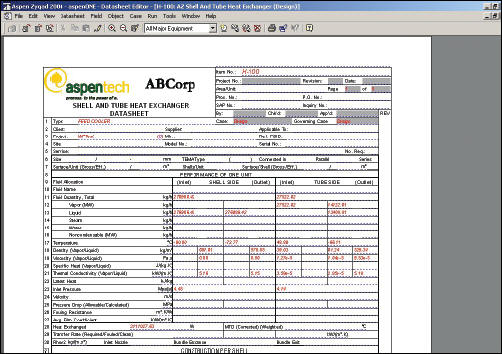

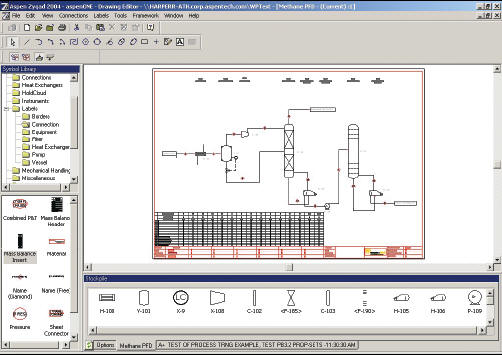

Aspen Basic Engineering is an industry-leading process engineering solution that enables global organizations to seamlessly and accurately tie together all aspects of front-end design and basic engineering. Powerful and comprehensive, it integrates all major process simulation programs, equipment design programs, cost estimation and in-house design tools. Flexible out-of-the-box Datasheet and PFD and P&ID creation tools . help streamline engineering workflows, enabling faster, more efficient collaboration across the organization. Aspen Basic Engineering

In addition to providing an accurate and constantly updated information source for process design, Aspen Basic Engineering offers a robust set of out-of-the-box design deliverables, such as multi-disciplinary datasheets, PFDs, P&IDs, and equipment lists. To support downstream engineering workflows, Aspen Basic Engineering enables the expansion of simulations to process flow diagrams and process flow diagram to P&IDs, maintaining design information and consistent connectivity. Aspen Basic Engineering also supports the transmittal of basic design data to detailed design, providing an interface to Intergraph and AVEVA systems. Aspen Basic Engineering further manages process design information throughout the lifecycle of a facility. This enables engineering teams to share process and equipment information in a secure, access-controlled environment while debottlenecking the process. Benefits As an industry-leading process engineering solution, Aspen Basic Engineering improves the basic engineering function, enables rapid transition from concept engineering to basic engineering, and allows for the delivery of electronic data to detailed design and procurement. Worley Parsons, a global E&C organization servicing the process industry, employs Aspen Basic Engineering to: Features Lifecycle Engineering Data Repository Design and Deliverable Templates and Views Design Tools Integration Cost Estimation Integration Concurrent Engineering Support Engineering Processes Detailed Engineering Integration Design Re-Use and Process Licensor Application Configurable to Your Standards and Systems The Scope of aspenONE Process Engineering

|

|---|

地址: 北京市朝阳区北苑路168号中安盛业大厦1403室 邮编: 100101 |